Structural change with hydrogen

The energy transition towards a decarbonized economy is heralding in a profound transformation in energy-intensive industry. To achieve this, a range of technologies must be combined to create a hydrogen value chain, starting with the development of efficient electrolyzers and fuel cells for mobile and stationary applications, via practicable methods for storage and transport right up to the cost-effective series production of such systems. In order to develop holistic solutions for this range of topics, Fraunhofer IWES and Fraunhofer IWU are constructing the Hydrogen Lab Görlitz (HLG) together, which is being funded by the Free State of Saxony and the Federal Ministry for Economic Affairs and Climate Action (BMWK).

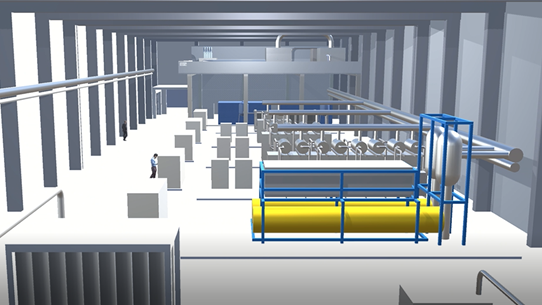

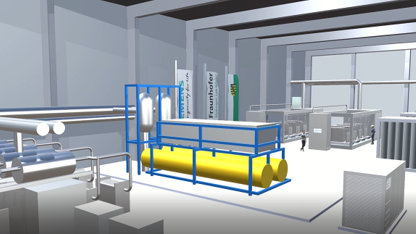

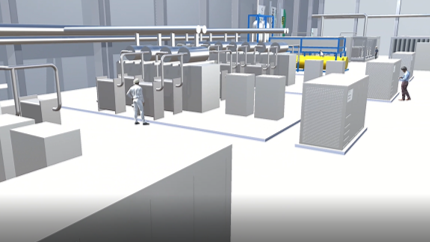

The HLG will provide a research and development platform for the power-to-H2-to-power value chain, which is crucial in the industrial and mobility sectors. To this end, a chain of electrolyzers, pipeline systems, H2 storage units and fuel cells with a total capacity of 12.3 MW will be installed.

In addition to the development of production technologies for electrolyzers and fuel cells suitable for large-scale production, the research activities focus on the digitalization of hydrogen technology. The modeling of individual components and their digital integration into a virtual overall model along defined interfaces allows for a distributed development of optimized plants, which will be supported by modern database systems.