Green hydrogen in the chemical industry

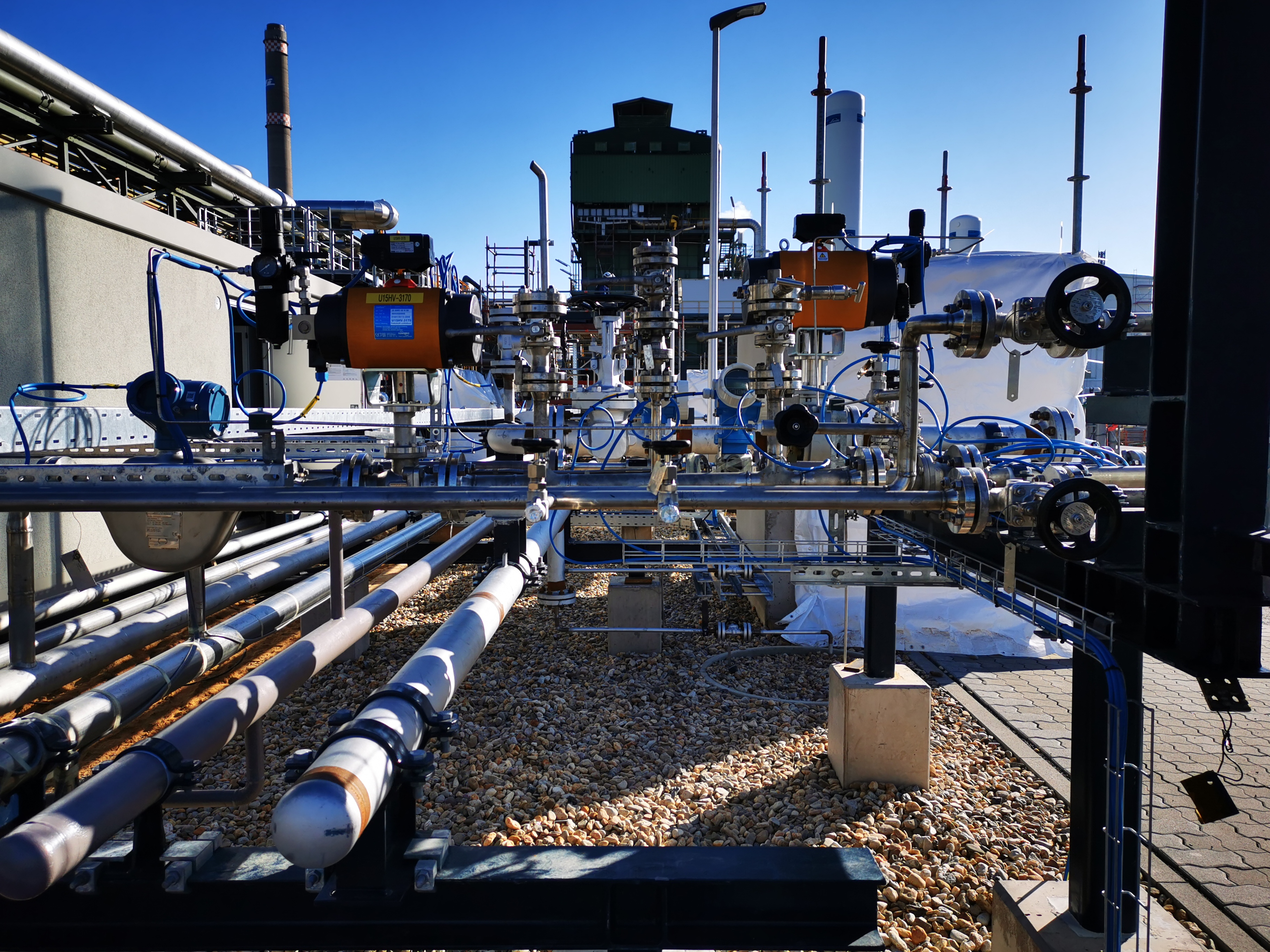

In the Central German Chemical Triangle, the Fraunhofer-Gesellschaft is paving the way for a new generation of test infrastructure with the commissioning of the Hydrogen Lab Leuna (HLL). Embedded in the supply network of the InfraLeuna chemical park, the HLL boasts five test pads and a technical center plant for electrolyzers up to 5 MW, which are supplied with deionized water, steam, compressed air, nitrogen, hydrogen, and CO2. The green hydrogen produced is analyzed on site, purified, and fed directly into the 157-km-long H2 pipeline, from where it is distributed to the industrial sites in the region for use in chemical processes.

The HLL offers the capacity for testing industrial-scale electrolyzers of any type – be that PEM, AEL, AEM, or SOEC – in 24/7 continuous operation, with the possibility of simulating dynamic load profiles during operation with electricity from photovoltaic systems and wind turbines. This enables an assessment of their performance, cost-efficiency, and long-term behavior in real-world operation as well as in accelerated aging tests. The data collected will provide the basis for future certification that is key in providing operators with assurance about the reliability and efficiency of such plants.

Fraunhofer IWES’ competencies in electrochemical analysis make it possible to trace degradation phenomena on critical components such as membranes and bipolar plates back to material properties and utilize these findings for the development of improved materials and components. To this end, additional test rigs for electrolyzer stacks up to 50 kW will enable the investigation of new components and operation under particularly challenging conditions (mechanical and thermal stress) in a technical center plant to be completed by mid-2022. The green hydrogen produced in the HLL can be used on site in power-to-X processes for the sustainable synthesis of commodity chemicals. The integration of the HLL into the Leuna chemical hub and its supply network allows model processes for sector coupling to be demonstrated and tested under realistic conditions directly at the chemical industry site – and on an industrial scale. For example, Fraunhofer is currently developing a pilot process for the production of methanol from CO2 and green hydrogen in collaboration with TotalEnergies and Sunfire in the eCO2Met project.